Forging fixtures are one of the vital tools in the automotive industry that are used to produce chassis blades. These fixtures play a very important role in creating precision and high quality chassis blades. In this article, the introduction and performance of chassis blade tattooing fixture is discussed.

1. Definition and importance of tattoo fixtures:

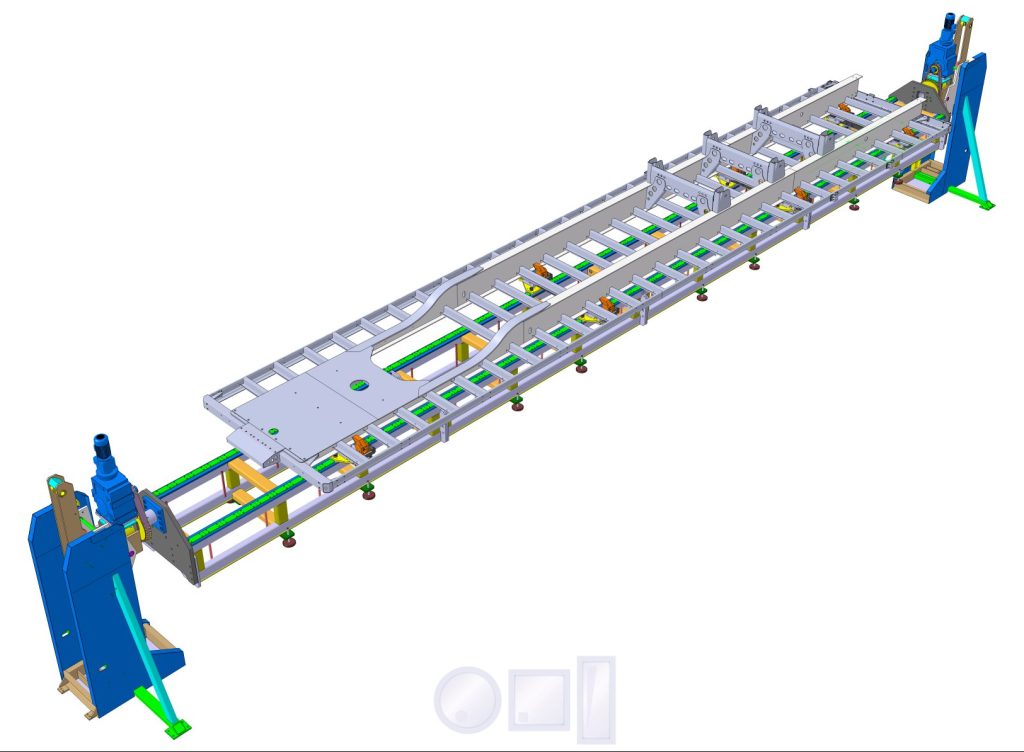

Chassis blade tattooing fixtures are tools that are used in different stages of chassis blade production. By creating strategic and specific points on the blade, these tools allow the tattooing process to be carried out with high precision and without any unwanted movement. Chassis blade tattooing fixture

2. Components and structure of tattoo fixtures:

Chassis blade tattooing fixtures are usually made of durable and precise metal parts. These components are:

a. Fixture frame:

This part acts as the main part of the fixture and all other parts are connected to it.

b. Pins and Nuts:

Pins and nuts are used in the fixture to precisely place the blade in the correct and fixed position.

J. Height adjustment system:

This system helps to adjust the precise height of the chassis blade to minimize height errors in the tattooing process.

of the. System Configuration:

To prevent unwanted movement of the blade during tattooing, a stabilization system is created using pressures and locks.

3. Performance of tattoo fixtures:

Chassis blade tattooing fixtures are designed in such a way that the blade is firmly placed in the desired position and does not have any unauthorized movement. These tools help to control and guarantee the accuracy and quality of products in the stages of pre-tattooing and tattooing of the blade.

4. Benefits and effects:

a. High accuracy:

Due to their precise and adjustable design, tattooing fixtures provide high precision in the production of chassis blades.

b. Increase production speed:

The use of tattooing fixtures leads to an increase in the speed of the production process because the time required to adjust and determine the position of the blade is reduced.

J. Improve quality:

The use of tattooing fixtures improves the quality of chassis blades and reduces problems caused by differences in settings.

Conclusion:

Chassis blade tattooing fixtures help improve performance and quality in the automotive industry by creating a precise and stable system. By using these vital tools, it is possible to produce chassis blades with high precision and superior quality on a continuous basis.