mission statement

Creating ideas & own changes

Designing and manufacturing all kinds of trailer line products and machines and the first professional collection in Iran to provide engineering services to trailer manufacturing companies

Automation of all industrial and production activities performed by humans, as well as upgrading and optimizing existing machines

Carrying out related activities to register ideas and commercialize works Consulting and engineering services for companies and institutions

Carrying out innovative projects and helping domestic researchers and science owners to commercialize their ideas and inventions into new products, becoming a sales center for engineering and scientific products and providing professional support to them.

If you have a production line in your industrial unit, you must make sure that the production line is working optimally.

Industrial machines and devices are constantly suffering from different problems. These problems can be in different parts, including the mechanics of the device, electricity or its control.

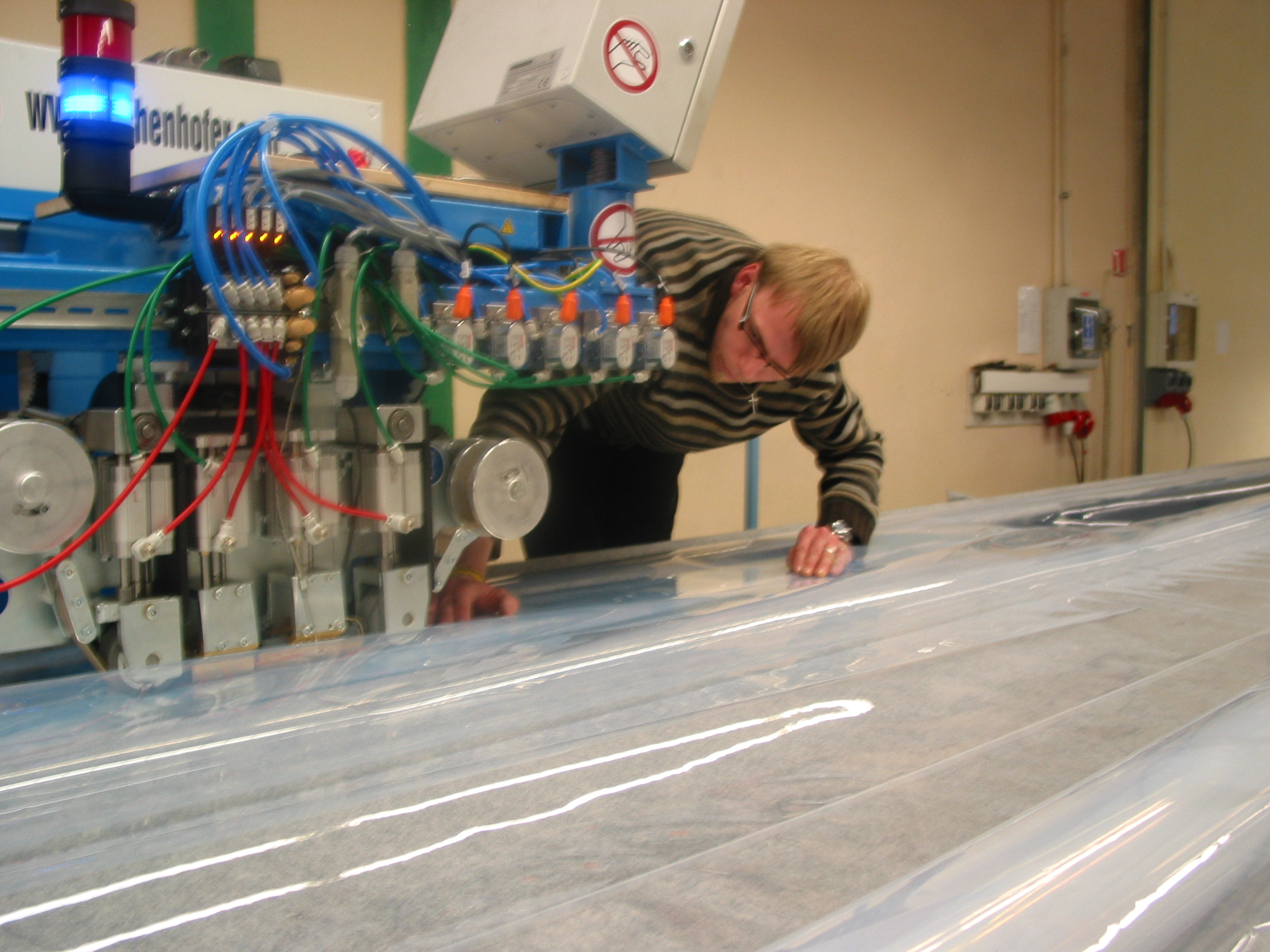

You may be looking for the design and manufacture of custom industrial machines and devices. A device that does not have an example in the country or that you intend to implement your idea in a practical way.

Using the best experts in the field of designing industrial devices, has the honor to carry out all your orders for the design and construction of industrial machines based on the current standards of the world.

By employing creative, young, committed, professional, expert people with new ideas

By using creative, expert and professional people in the field of manufacturing all industrial tools, sheds, steel tanks, etc.

Design, construction and implementation of all industrial projects with the highest quality and standard grade

Designing, building and implementing all kinds of sheds, all kinds of tankers, all kinds of steel tanks and steel pipes, all kinds of industrial machines and...

By innovating in our systems, we improve the limits of mobility, skill and intelligence in our systems, and cause precise and controllable movements that are beyond human ability, therefore, the mechanisms designed in this collection have the ability to move freely. And it increases the reliability of movement and eliminates errors.

PLM provides the upstream platform for product creation and engineering data management. At the concept phase, product creation processes allow for flexibility and creativity with limited or no change management, with the ability to reuse data from past products. As products mature, the data management process becomes tighter, change management kicks-in, and more organizational functions are required to collaborate to make things happen.

Enterprise resource planning (ERP), product lifecycle management (PLM) and manufacturing execution systems (MES) have traditionally been three very distinct pillars of the manufacturing technology puzzle. But in today’s world—where timely product delivery and top-notch quality are the hallmarks of success—those individual pieces are coming together to create a foundation for a modern-day interpretation of lean manufacturing

MES is the de facto shop floor performance and operations management engine behind most mass-production control activities. It regroups all plant-wide manufacturing decisions, focusing on rapid actions, detailed planning, forecasting, continuous improvement, planned and actual metric analysis and ongoing adjustments.